Coatings make more efficient use of bearing materials and eliminate secondary machining and installation.

Dry, unlubricated insert bearings excel in jobs where it’s tough to maintain oil and grease lubrication. Applications for insert bearings include sliding and rotating rods in shock absorbers, air cylinders, gas springs, solenoids, valve shuttles, small pumps, servomotors, and hydraulic and mechanical actuators. Bearings made of glass and bronze-filled PTFE or nylon go in machined bores and housings and are held in place by press fits, snap rings, staking, or pins.

Most of the bearing material is wasted because just a few thousandths of an inch supports an entire load. Coatings are considered an attractive alternative because they make more efficient use of bearing materials and eliminate secondary machining and installation. However, most conventional coatings and application methods don’t meet typical tolerance or load specs.

But a direct-bonding process from Dimension Bond, Chicago, Ill. (http://www.dimensionbond.com/), overcomes these limitations. It applies composite bearing materials to load-carrying surfaces with ±0.0002-in. tolerances, well within specs of even instrument bearings. A noncontact sensor measures part size before, during, and after the application process.

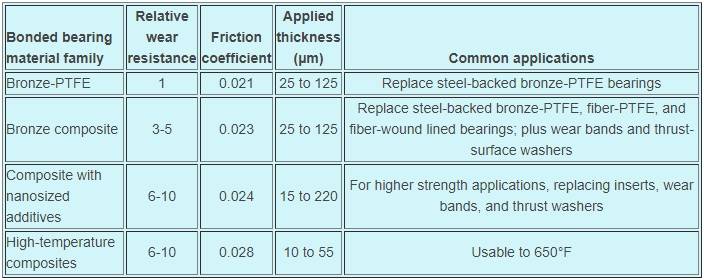

The approach works with any liquid-based, thermal-cure system. Dimension Bond’s bronze-PTFE direct-bond materials are equivalent to PTFE-bronze insert bearings. Even-higher-strength formulations may combine engineering polymers and nanosized particles. Friction coefficients down to 0.021, PV limits exceeding 53,000, and continuous service temperatures to 675°F are possible.

Direct-bonded bearings also tend to better withstand chemical attack and foreign particles than their insert counterparts, and they won’t dislodge in use. The high-strength, nonabrasive qualities of bonded bearings produce little or no dimensional change of wear surfaces over component lifetimes. In contrast, some fillers in conventional bearings, particularly glass, tend to harm mating surfaces, accelerating wear and cutting seal life.

Assemblies containing bonded bearings are often simpler, lighter, and less costly than those with conventional insert bearings. For example, a shock-absorber OEM converted to direct-bonded bearings and eliminated assembly costs associated with bearing inserts and wear bands. All told, the conversion pared 28% from the rod-guide cost and 32% from the piston.

Design for direct-bonded bearings

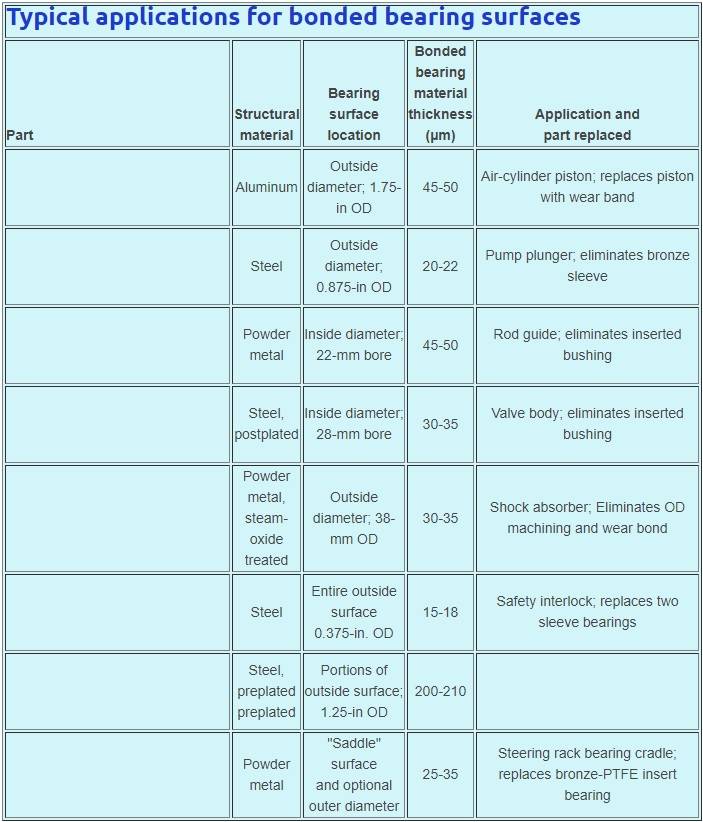

Most symmetrical part shapes can receive a bonded surface: cylindrical, round, flat, square, or conical. The materials bond to a variety of substrates, including brass, stainless and mild steel, aluminum (plate, die cast and permanent-mold castings, hard-anodized), powder metals (raw and steam-oxide treated), many filled and unfilled engineering plastics, and ceramics.

A composite bearing surface is applied to one or more bearing and wear surfaces to a thickness of 5 to 210 µm. Bearing surfaces go on parts opposing those with surface treatments such as hard-chrome plating. In the absence of surface treatments, the part with the greater swept area gets direct-bonded. As a rule, candidate parts should weigh less than 5.5 lb.

The maintaining of tolerances is another benefit of direct bonding. Tools used to machine bores and press bearings wear over time and can cause dimensional drift. Direct-bonding helps compensate for these size inconsistencies so finished parts meet tolerance specs. This compensation process can adjust finished-part tolerances to within ±0.0007 in. However, for best results, direct-bonded substrates should be held to within ±0.0015 in. For example, a 0.879 ±0.0015-in.-ID powder-metal rod guide bore with a 0.875 ±0.0007-in.-ID bonded bearing has a tolerance equal to the bearing surface itself. In SPC terms, the bonded-bearing surface boosts part CPK from 0.85 (raw part before bonding) to 1.58 (after bonding).

Longer-lasting shock absorbers

Shock absorbers damp vibration by metering hydraulic fluid through an orifice located between rod and bearing surfaces of the rod guide. Most designs make rod guides from split-ring, glass-reinforced, bronze-PTFE bushings.

An industry-standard wear test for shock absorbers applies a biaxial load at two frequencies to simulate road conditions. Rod guides should last 1.25-million cycles without failure. However, the glass fibers tend to wear rod surfaces. Over time, concentricity and parallelism between mating parts degrades. This allows more fluid to pass through the orifice, compromising damping properties. But replacing the split-ring rod guide with a direct-bond bearing surface 45 to 50-mm thick greatly improves concentricity and parallelism over the design lifetime.

Originally posted by Machine Design Magazine